In the course of digital transformation, mobile machines are becoming smarter, more connected, and more efficient. Industry 4.0 opens up new possibilities for automating machine functions, optimizing energy consumption, and designing predictive maintenance processes.

As specialists in hydraulic drive technology, system simulation, and data-based analysis, we accompany you on your journey to smart mobile machines. We support you in the digitalization of your systems—from sensor-based data acquisition and the analysis of operating data to the simulation-supported optimization of components and processes.

Our solutions enable you to collect status information in real time, analyze operating conditions, and make data-driven decisions. This not only increases the efficiency and reliability of your machines, but also lays the foundation for innovative business models – for example, in the areas of predictive maintenance or digital twins.

We Offer You These Fluid Technology 4.0 Solutions

-

Onboard data analysis and real-time simulation: Optimise the performance of your machines with precise analyses directly at the source and use real-time simulations for additional functionality.

-

Mobile data transmission of measurement and simulation data: Monitor and control machines from anywhere. Important data is transmitted securely and quickly via mobile radio.

-

Customer-specific cloud solutions: Use customised cloud technologies to analyse and visualise your telemetry data. Identify trends, optimise processes and minimise downtime.

Our Fields of Application

- Field testing: Improve your prototypes and machines with data-based testing in real-world applications.

- Diagnostics during function development: Identify problems early on and ensure smooth development.

- Condition monitoring: Gain valuable insights into the condition of your machines and plan maintenance measures more efficiently.

Source: Image taken from website

Partnership for Smart IoT-Solutions in Fluid Power

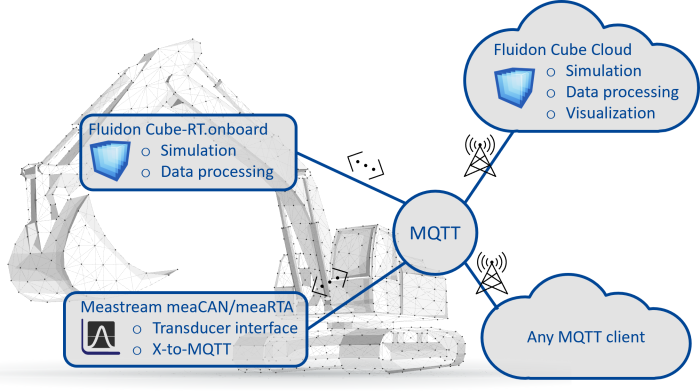

Our customised solutions are based on the combination of our extensive know-how in the simulation of complex mechatronic-hydraulic systems and their control, together with the expertise of our partner meastream. While we focus on the simulation and measurement data processing, meastream is responsible for the development and programming of the robust IoT hardware that is used directly in your application to efficiently collect and pre-process data.

meastream meaCAN

- CAN-to-MQTT adapter with real-time Linux OS

- Open source Eclipse Mosquitto™ MQTT message broker

- Dual fully isolated CAN transceivers with data rates up to 1 Mbps

- Real-time CAN message handling and pre-processing

- Ethernet, USB and HDMI

- +12V to +24V power supply

meastream meaRTA

- Analog-to-MQTT adapter with real-time Linux OS

- Open source Eclipse Mosquitto™ MQTT message broker

- 4-channel 10 Vpp differential analog interface with up to 768 kHz sampling

- Programmable real-time filters and advanced data pre-processing (c++ interface)

- Ethernet, USB and HDMI

- +12V to +24V power supply

Fluidon Cube-RT.onboard

- Sensor or control signals are used as input for the real-time simulation of your machine (onboard digital twin) or a real-time data analysis. The analysis or simulation results are continuously output via MQTT.

- The analysis algorithms and simulation models are integrated into the real-time environment via the standardised Functional Mockup Interface. They can therefore be created in a variety of applications.

- The system is based on a real-time Linux. This means that the appropriate hardware is available depending on the application and the computing power required.

Fluidon Cube Cloud

- The cloud application receives all data from the machine and the onboard data analysis and simulation available via MQTT.

- The dashboard enables the visualisation of the data.

- Flexible, definable workflows for further data processing – in combination with parallelisation and scalable computing power – allow for everything from simple data evaluations to complex AI-based analyses.

Discover Our Fluid Technology 4.0 Solutions for Mobile Machines!

Are you looking for a customized solution for your mobile machines and interested in our systems? Or do you have any questions or suggestions you would like to share with us?

Then get in contact with us and arrange a no-obligation consultation.