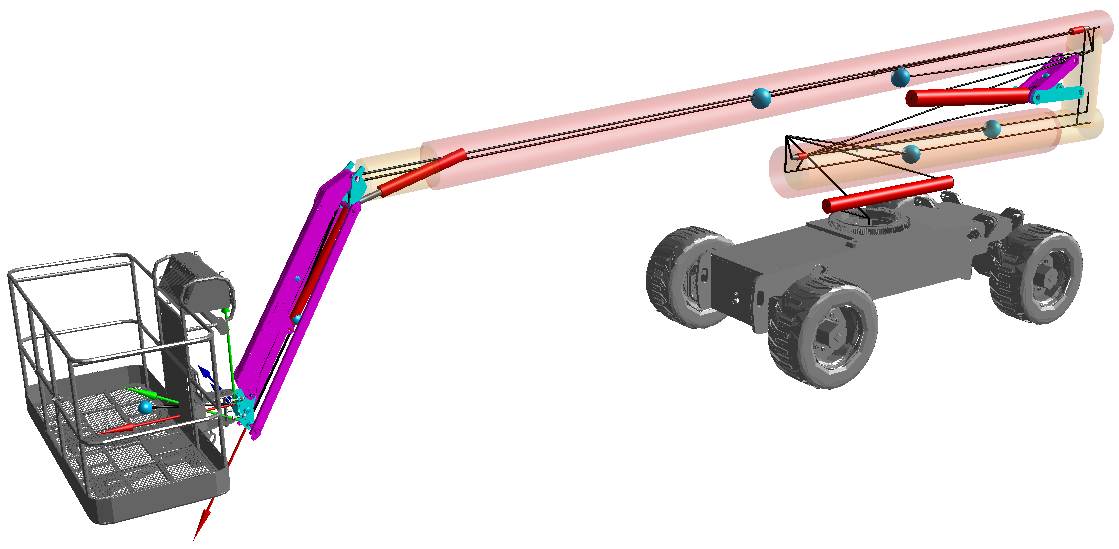

Trajectory control for user-friendly control of multi-axis movements

FLUIDON and meastream jointly present their prototype at the 13th IFK in Aachen from June 14 to 15.

FLUIDON GmbH, experienced service provider for simulation and analysis of fluid power and mechatronic systems, will present the prototype for a user-friendly control of multi-axis movements developed together with meastream GmbH, partner in the field of automation technology and mechatronic systems.

The combination of meastream’s expert knowledge in technical mathematics, trajectory calculation and automation and FLUIDON’s know-how in the simulation of complex mechatronic-hydraulic systems and their control is a condition for the development of the trajectory automation and 3D control system. The jointly designed solution provides the user with a convenient interface, no longer requiring user input for each individual machine axis.

The Fluidon Cube serves as a tool for the model-based development of mechatronic-hydraulic systems: Its Virtual Engineering Lab was used for designing the control system and suitable axis controllers.

Users of trajectory automation or 3D control benefit from increased operating speed and productivity, considerable savings in working time and can focus on their core task. In addition, smooth platform motion is achieved, safety is improved, and extensive operator training can be eliminated.

"The demonstrator developed together with meastream GmbH is a great example of advanced collaborative engineering," enthuses Dr Heiko Baum, Managing Director FLUIDON GmbH. "Fluidon Cube - The Virtual Engineering Lab - has been developed to support this creative process. The shared development space, unified interfaces, better system integration, faster simulation results, automated result evaluation and presentation allow you to focus on core competencies and increase productivity and solution quality."

Learn more about the application potential of the Fluidon Cube and see our trajectory control prototype in action in our exhibition booth 12 at the 13th IFK.

The combination of meastream’s expert knowledge in technical mathematics, trajectory calculation and automation and FLUIDON’s know-how in the simulation of complex mechatronic-hydraulic systems and their control is a condition for the development of the trajectory automation and 3D control system. The jointly designed solution provides the user with a convenient interface, no longer requiring user input for each individual machine axis.

The Fluidon Cube serves as a tool for the model-based development of mechatronic-hydraulic systems: Its Virtual Engineering Lab was used for designing the control system and suitable axis controllers.

Users of trajectory automation or 3D control benefit from increased operating speed and productivity, considerable savings in working time and can focus on their core task. In addition, smooth platform motion is achieved, safety is improved, and extensive operator training can be eliminated.

"The demonstrator developed together with meastream GmbH is a great example of advanced collaborative engineering," enthuses Dr Heiko Baum, Managing Director FLUIDON GmbH. "Fluidon Cube - The Virtual Engineering Lab - has been developed to support this creative process. The shared development space, unified interfaces, better system integration, faster simulation results, automated result evaluation and presentation allow you to focus on core competencies and increase productivity and solution quality."

Learn more about the application potential of the Fluidon Cube and see our trajectory control prototype in action in our exhibition booth 12 at the 13th IFK.