Fluid 4.0 - Implementation of Digitalization for Fluid Power Technology 4.0

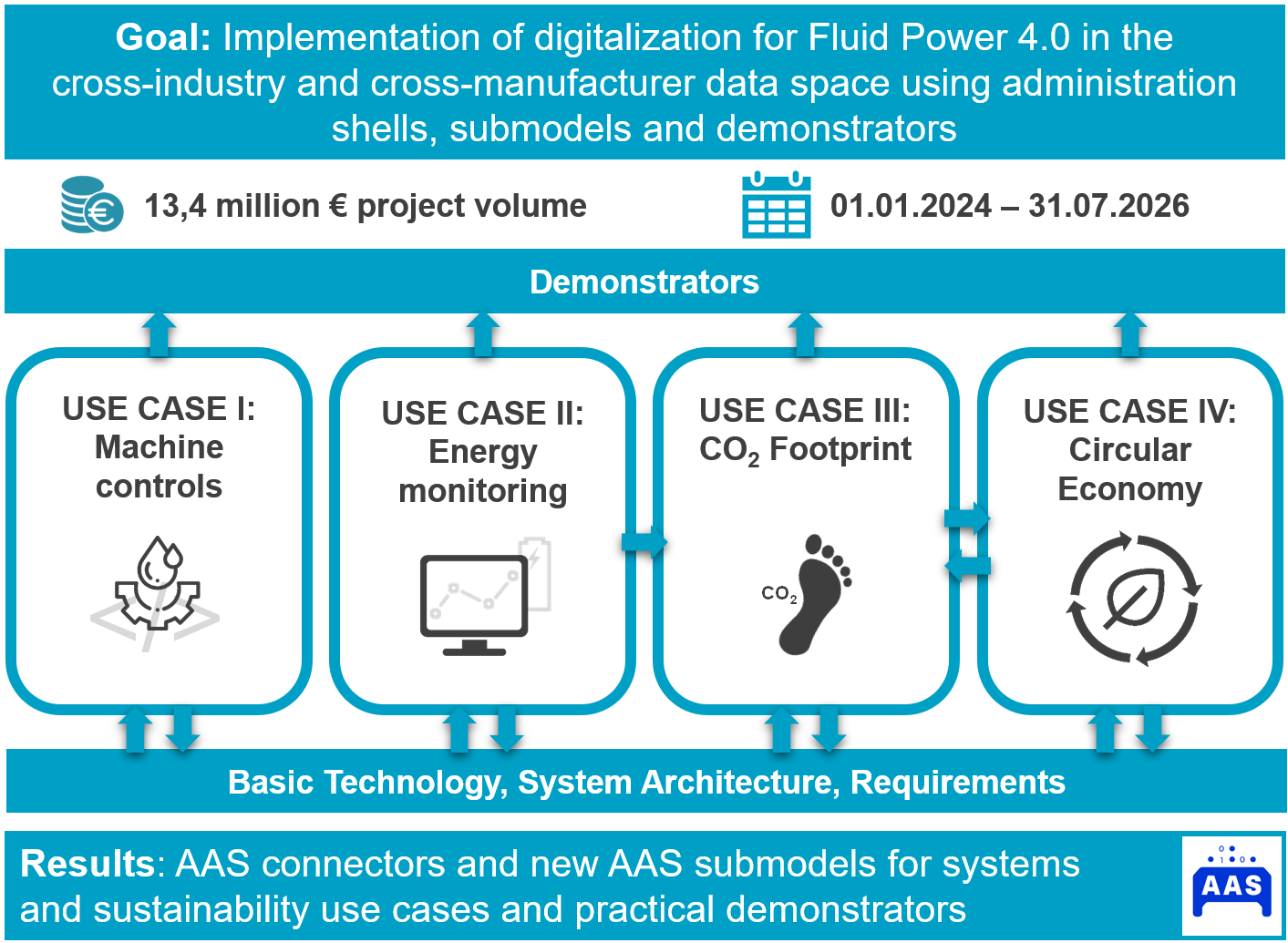

In the Fluid 4.0 project, fluid technology manufacturers, machine and system manufacturers, users and service providers are working together on the digitalisation of fluid technology using asset administration shells, submodels and demonstrators. Both specific applications and overarching challenges are being addressed.

FLUIDON is actively contributing its extensive expertise in the simulation of fluid technology systems to the project. It is developing an Industry 4.0-compliant simulation solution and the associated infrastructure for the integrated and digital engineering of fluid technology systems.

Fluid power – key technology with economic significance

- Fluid technology (hydraulics & pneumatics) generates around 9.6 billion euros annually in Germany, with an export ratio of 60%.

- Fluid technology products offer high flexibility, dynamics, reliability, robustness and power density with low weight. They are essential components in stationary and mobile mechanical engineering.

Shaping the future of fluid technology with data and digitalization

- The diversity of variants and flexibility of use of fluid technology components generate large amounts of data - essential for future value chains.

- Industry 4.0 promotes efficiency, increased productivity and new business models with economic and ecological benefits.

- The cross-manufacturer exchange of data is fundamentally changing the entire value creation system.

Standardization through AAS – digital twins in fluid technology

- In contrast to many other industries, there are no standardized application scenarios or predefined inputs and outputs in fluid power.

- This diversity requires flexible yet structured solutions for digital integration.

- The VDMA Fluid Technology Association has developed a digitalisation concept based on the principle of the digital twin.

- The central element is the Asset Administration Shell (AAS) – the digital image of real components.

- The AAS enables cross-vendor data exchange and creates compatibility with established standards such as OPC UA and AutomationML.

Goals & benefits

- Maximum interoperability, future readiness, and a solid foundation for Industry 4.0 in fluid power technology

- Improved collaboration between manufacturers, machine builders, end users, and service providers

- Components with a digital twin: In the future, manufacturers will deliver physical products together with an Asset Administration Shell (AAS)

- Efficient data processes: Machine and plant builders will integrate digital twins seamlessly into data-driven workflows and Industry 4.0 data management

FLUIDON Demonstrates the Practical Use of AAS in Fluid Power Simulation

FLUIDON showcases how the AAS submodel “TechnicalData” can be used to automatically parametrize fluid power simulation models within the SaaS environment Fluidon Cube. The goal is to calculate, for example, the CO₂ footprint of a production process and store the results in a structured manner in the AAS submodel “Carbon-Footprint.”

In addition, FLUIDON demonstrates how simulation tools can be connected via the AAS submodel “Asset Interfaces Description” and the MQTT protocol – a key enabler for networked, interoperable Industry 4.0 systems.

Who Is Behind Fluid 4.0 – An Overview of the Project Consortium

A consortium of experts and companies has joined forces to tackle the current deficits and challenges in the digitalisation of fluid technology. Together, they are developing innovative solutions in the following key areas:

- Cross-industry, machine-readable data provision for fluid technology systems - the basis for a networked fluid technology data space.

- Intelligent administration shells at system level that optimally link and expand the existing infrastructure at component level.

- Domain-specific digital services that are specially developed for fluid technology applications.

- Networked interfaces between manufacturers and users that enable seamless integration into existing data standards, digitalisation technologies and engineering tools.

- Cross-life cycle CO₂ balancing and circular economy concepts to create sustainable and resource-saving solutions for fluid technology.

- Integrated digital engineering for the efficient development and optimisation of fluid technology components.

This project paves the way for future-proof, digitally networked fluid technology that is more efficient, more sustainable and better integrated than ever before.

From Concept to Realization – The Fluid 4.0 Work Program

As part of the project, FLUIDON is focusing on innovative solutions for the digitalisation of fluid technology, with the following key areas:

- Integration of simulation models into the I4.0-compliant data space to create a seamless digital process chain.

- Development of intelligent administration shells that link component simulation models to create a comprehensive overall system simulation.

- Development of an I4.0-compliant simulation solution and infrastructure as a basis for a wide range of digital services in fluid power applications.

- Ensuring seamless integration of simulation-based engineering methods that can be combined with conventional methods without data consistency breaks.

- Supporting our project partners in implementing simulation-based services in the emerging I4.0-compliant simulation framework.

- Development of a powerful system simulation with high numerical stability based on FMI Co-Simulation.

- Design of an interoperable simulation interface based on the administration shell to enable standardised data access.

- Analysis and calculation of the energy consumption of fluid power components in operation for CO₂ footprint balancing.

With these measures, FLUIDON is driving the digital transformation of fluid power and creating a scalable, interoperable and sustainable simulation solution for Industry 4.0.