Webinar: Optimierung von Öl- und Gas-Rohrleitungssystemen mit DSHplus

Anmeldung und Informationen zum kostenfreien Webinar am 8. November, um 16:00 Uhr. Referent ist Dr. Heiko Baum, Geschäftsführer FLUIDON GmbH.

Das internationale Webinar wird auf Englisch abgehalten.

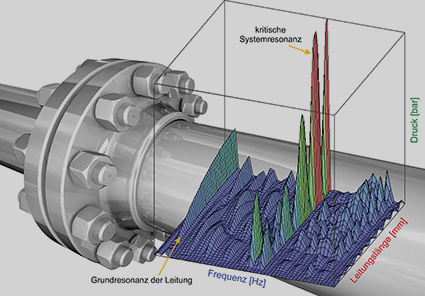

Optimization of oil and gas pipelines by pressure pulsation analysis will protect systems regarding disturbing noise emissions, permanent component stress, reduced system functionality and a higher failure rate of the system.

Pulsation is inherent in all reciprocating equipment such as compressors and pumps, screw compressors, and any other type of equipment used to move gas or liquid.

To ensure functional pipeline systems, with long durability and minimized noise levels, the overall system's characteristics must be considered. The conception of a well-designed pipeline system starts with a pressure pulsation analysis.

In this webinar ‘RohrLEx’, FLUIDON piping expert, explains the relationship between pressure pulsations and pipeline problems and the advantages in using differently specialized software for this process of optimization. So, he presents both an automatic analysis of pressure pulsations in piping systems with DSHplus and HyperStudy as well as the integration of a control created in Activate.

Webinar Outline

- Special features and requirements of oil and gas piping systems

- Challenges in optimization (e.g. pulsation damping remedies, water hammer effects)

- Unrivalled expertise and DSHplus for optimization of piping systems

- Advantages in using DSHplus together with HyperStudy and Activate

- Guided and supported instead of lost in simulation

Who Should Attend?

Engineers involved in the construction of piping/pipelines or using them in any way, irrespective of the material, cross-section, pipe length or type of fluid, from industries such as industrial and mobile hydraulic equipment, process engineering and oil and gas industry.

As in Automotive, Aerospace, Marine, Manufacturing, Medical Technology, Fluid Power, Science and Education.

Optimization of oil and gas pipelines by pressure pulsation analysis will protect systems regarding disturbing noise emissions, permanent component stress, reduced system functionality and a higher failure rate of the system.

Pulsation is inherent in all reciprocating equipment such as compressors and pumps, screw compressors, and any other type of equipment used to move gas or liquid.

To ensure functional pipeline systems, with long durability and minimized noise levels, the overall system's characteristics must be considered. The conception of a well-designed pipeline system starts with a pressure pulsation analysis.

In this webinar ‘RohrLEx’, FLUIDON piping expert, explains the relationship between pressure pulsations and pipeline problems and the advantages in using differently specialized software for this process of optimization. So, he presents both an automatic analysis of pressure pulsations in piping systems with DSHplus and HyperStudy as well as the integration of a control created in Activate.

Webinar Outline

- Special features and requirements of oil and gas piping systems

- Challenges in optimization (e.g. pulsation damping remedies, water hammer effects)

- Unrivalled expertise and DSHplus for optimization of piping systems

- Advantages in using DSHplus together with HyperStudy and Activate

- Guided and supported instead of lost in simulation

Who Should Attend?

Engineers involved in the construction of piping/pipelines or using them in any way, irrespective of the material, cross-section, pipe length or type of fluid, from industries such as industrial and mobile hydraulic equipment, process engineering and oil and gas industry.

As in Automotive, Aerospace, Marine, Manufacturing, Medical Technology, Fluid Power, Science and Education.