Assistance System for 3D Trajectory Control of Multi-Axis Systems

Challenge

Mobile machines have a large number of individually controllable degrees of freedom. In the mobile elevating working platform shown, for example, up to 8 hydraulic axes must be controlled in parallel by the operator to enable smooth movement in the space of the platform along a path curve. In addition, the control of the platform position requires the operator to think in axis coordinates of the drive systems. In summary, the operation is very complicated and requires a lot of experience and a high level of attention from the operator.

Goal

Development of an assistance system for simplified and safe operation of multi-axis systems with the following features:

- Intuitive direction specification of the platform front in global x-y-z coordinates

- Partially automated traversing of predefined path curves - operator defines a target and controls only the traversing speed

- Compensation of disturbance variables such as vibrations and friction

Benefit

The simplified operation brings several advantages at once:

- Better focus of the user on his core task

- Increased working speed and productivity

- Smooth platform movement

- Improved safety

- Reduced need for training

DALL·E - A truck-mounted work plattformwith elements of IoT and Industry 4.0.

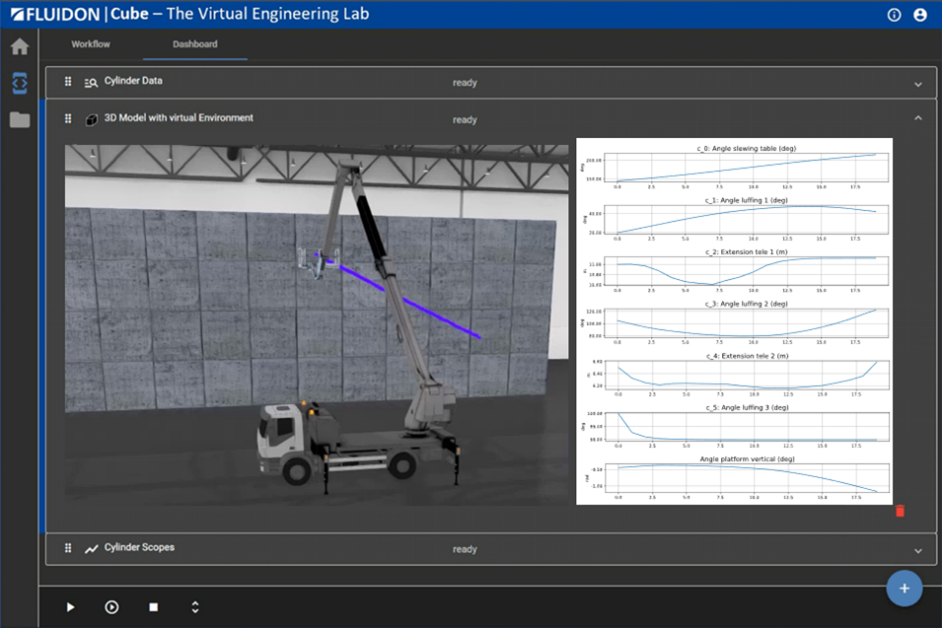

Model-Based Development With Real-Time Capable Digital Twin and Hardware-in-the-Loop

The assistance system was developed in close cooperation with the company meastream using a model-based approach.

The development of the trajectory planning and drive control is based on technical-mathematical models of the mobile elevating working platform, the so-called digital twin. Validation, testing and optimization of the assistance system is performed by coupling the real-time capable digital twin (RDT) with the targeted machine operating and control hardware in the hardware-in-loop (HiL) development environment of FLUIDON | Cube.

Development of the real-time capable digital twin

- Modeling of the RDT to represent the dynamic machine behavior

- Consideration of various domains by integration of encapsulated simulation models from different simulation tools by means of Functional Mock-up Units (FMU)

Development of the control algorithms by means of hardware-in-the-loop

- Coupling of the control hardware with the RDT in FLUIDON | Cube HiL

- Drive control and feedback control algorithms

- Implementation of the overall sequence control of the assistance system

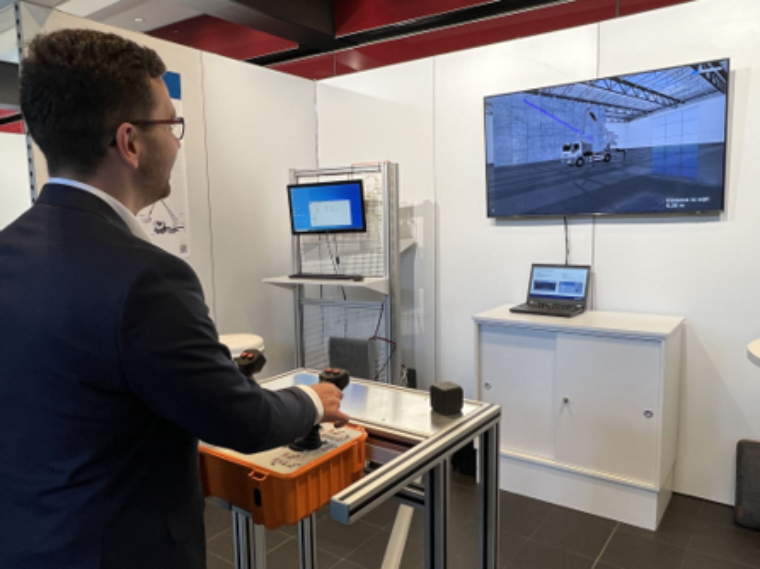

Development and testing of user interaction and user experience

- Integration of user hardware and coupling with 3D visualization

- User feedback on operation and user interface

Development of trajectory planning and calculation of drive state vectors

- Technical-mathematical description of the machine drive kinematics

- Development of algorithms for trajectory planning and calculation in space

- Calculation of individual drive reference variables (x, v/ ϕ, ω) for the spatial motion of the cage

- Consideration of optimization goals, such as the uniform and jerk-free motion of all drives or the minimization of the required drive power of the overall system

Additional Information

- FLUIDON Cube - The Virtual Engineering Lab

- Conference Paper: Müller et al. (2022) - 3D-Bahnkurvensteuerung eines Auslegers am Beispiel einer Hubarbeitsbühne

Detailed questions about the mentioned project or possible solutions for specific problems will be answered directly by our Engineering-Team.