Cavitating Flows and Gas Bubble Transport

The occurrence of cavitation negatively affects the performance of hydraulic systems. The impairments range from increased noise levels to severe and life-limiting erosive wear of machine parts. Cavitation in hydraulic systems can be prevented by early integration of one-dimensional fluid power simulation software into the design process.

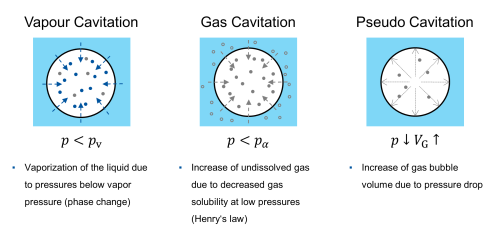

The expanded physical models of DSHplus enable the user to analyze all relevant types of cavitation – vapor cavitation, gas cavitation and pseudo-cavitation – as well as the associated phenomenon of gas bubble transport. The individual types of cavitation, their mathematical modelling and two practical examples are presented in detail in the subpages listed below.

The cavitation modelling in DSHplus is continuously improved. Within the scope of a research project, FLUIDON is currently developing a calculation approach to take into account the intrinsic dynamics of the gas bubbles, which has been neglected so far.