Pressure Measurement in Gases and Liquids

Welcome to our website on pressure measurement in gases and liquids! Whether you are a beginner in this field or already have experience, here you will find valuable information and resources to help you understand the basics and nuances of pressure measurement.

Quelle: Bild von Webseite entnommen

Pressure measurement is a critical component in many industrial and scientific applications. It enables us to monitor and control the safety, efficiency and reliability of systems that work with gases or liquids. From simple pressure gauges to state-of-the-art digital sensors, the technologies and methods for pressure measurement are diverse and offer solutions for almost every requirement.

Our goal is to provide you with a comprehensive understanding of the various pressure measuring devices and their applications. We offer guidance, tips and recommendations to help you select the right device for your specific needs, ensuring you always achieve accurate and reliable results.

Transient Pressure Monitoring

Independent of the actual type of fluid used, any hydraulic system with discontinuously operating components like opening/closing valves or dynamic actuators is subjected to pressure pulses. A change in flow rate by opening or closing a valve involves accelerating or decelerating a mass of fluid, which is always accompanied by a (initially) local change in pressure.

This pressure peak will then propagate through the system with the fluid’s speed of sound and will be intensified, reduced, divided or reflected whenever it meets a change in impedance. If the resultant pressure waves in the system merely present background noise or develop into damagingly high peaks is a matter of the initial intensity of the peak and its interaction with the system.

- Dynamic pressure peaks can be of short duration in the order of milliseconds

- Measuring these peaks requires high sampling rates and either peak hold or continuous monitoring

- Any filtering applied to measured pressures needs to reflect the potential dynamics of the system as not to miss critically high peak pressures

- Analog instruments are in no way suited to this task due to the inherently high damping of the gauge needles

- Simple digital manometer style devices may offer a peak hold feature, but often lack the sampling rate to detect the actual maximum value of a peak

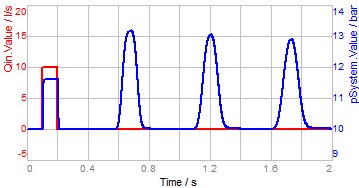

To demonstrate the problem, propagation of a pressure pulse through a long pipe (l = 300 m, d = 0,3 m, closed ends) is observed using a simulation model and different kind of sensors. By simulating the dynamic capabilities of the sensors, the results can be shown for the same sensor position in a single simulation run.

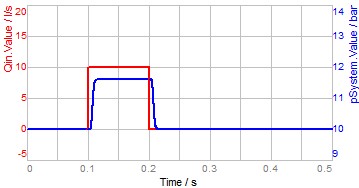

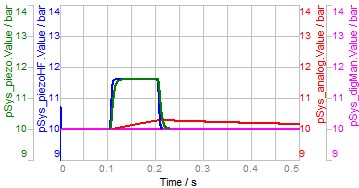

Measurement of a Short Time Pressure Pulse

- At t = 0.1 s a flow pulse of 10 l/s for 0,1 s is introduced into the pipe (red, e.g. from a discharging component, check valve etc.), creating a pressure peak of ̴11,6 bar (blue)

- 10 m downstream a sensor is reading the pipe pressure

- The signal readout of four exemplary sensor types is shown:

- Analog manometer type, reaction time <= 0,5 s (red)

- Simple digital peak hold manometer, readout time 0,25 s (magenta)

- Industrial piezo sensor, reaction time <= 0,005 s (green)

- Dynamic piezo sensor (blue)

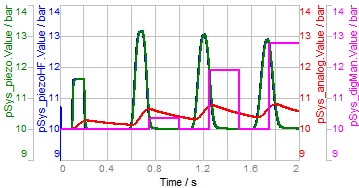

Measurement of Pressure Oscillations

The pipe is closed at both end and with a speed of sound of 1140 m/s reflections from the far end start to show at the sensor position from 0,5 s onwards.

- With a closed end condition, the reflection from the far end doubles in amplitude

- Over time the peaks slowly decrease due to friction at the pipe wall

Sensor readings:

- As can be readily seen, the fast piezo sensors will give an accurate value at all times (blue, green)

- If the peak hold functionality of the digital manometer (magenta) can catch the actual peak pressure depends on its readout time (and will change with frequency of the pressure oscillations and sensor position as well)

- The analog manometer (red) will miss short transients completely due the highly damped gauge (required for readability)