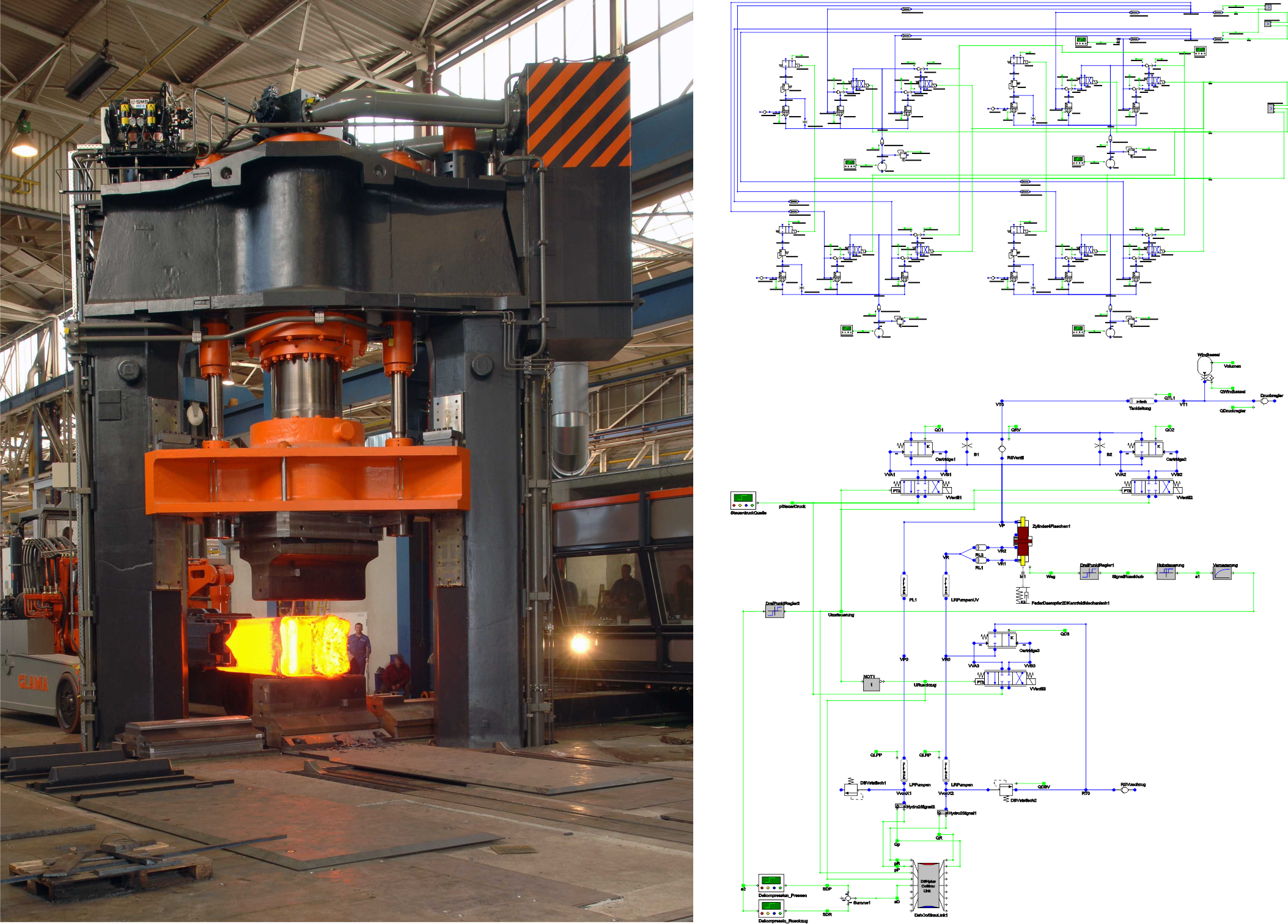

Powerful, High-Precision Open-Die Forging Presses

Challenge

In the forging industry, high precision and productivity, perfect micro-structural material properties as well as flexible application, batch size and single piece production are required.

Conditions

- Open-die forging presses are capable of generating forces of well over 200 MN

- High production speeds with tight forging tolerances are required.

Scope

Reliable hydraulics for maintaining tight forging tolerances at high stroke rates and forging forces

Solution

- Setup of a comprehensive simulation model of the press with pressure supply

- Inclusion of the tank line to check the system for water hammer and cavitation effects

- If required, the model can be extended with a multi-body model of the mechanics of the press for co-simulation via FMI standard

Detailed Information

Detailed questions regarding the above-mentioned projects or possible solutions to specific problems will be answered directly by our engineering team.

Customer Projects

Virtual commissioning - Realisation of closed-die forging presses (PDF)

Engineering Project

Dynamic simulation of an open-die forging press including a detailed model of the supply and Leitungssystem (PDF)

User Presentation

Real-time prediction of the forging dimension on open-die forging presses (PDF)