GUSMA – Coupled, cross-company simulation of mobile hydraulic machines for the digitalisation of product development

Increasing automation at all system levels and the fact that vehicle developments nowadays take place across companies and in development and supplier networks require a highly efficient product development process. Co-simulation is an important tool for this. Therefore, the purpose of the joint project Gusma, which was carried out at KIT, was to enable the use of co-simulation for cross-company simulation in the off-road industry.

Motivation

Computer-aided simulations have been used for several decades to simulate actual technical systems. In particular, they are employed to gain a better overall understanding of the system, to optimise the system or to predict its behaviour. This additional information during the product development process is intended to lead to a reduction in development time and costs while at the same time increasing product quality.

In order to represent a real system in the simulation in a computerised way, it is necessary to represent it by a model. From the point of view of a mechatronic overall system, this results in the requirement to model the specific properties of the respective domains mechanics, hydraulics, control, etc. according to the user's requirements.

Due to the handover of simulation models across company boundaries, the protection of company know-how is another important element in the project. For this reason, the research project will provide the possibility of protected (partial) model export. The model exchange and the coupling are to be carried out using a standardised procedure.

Solution

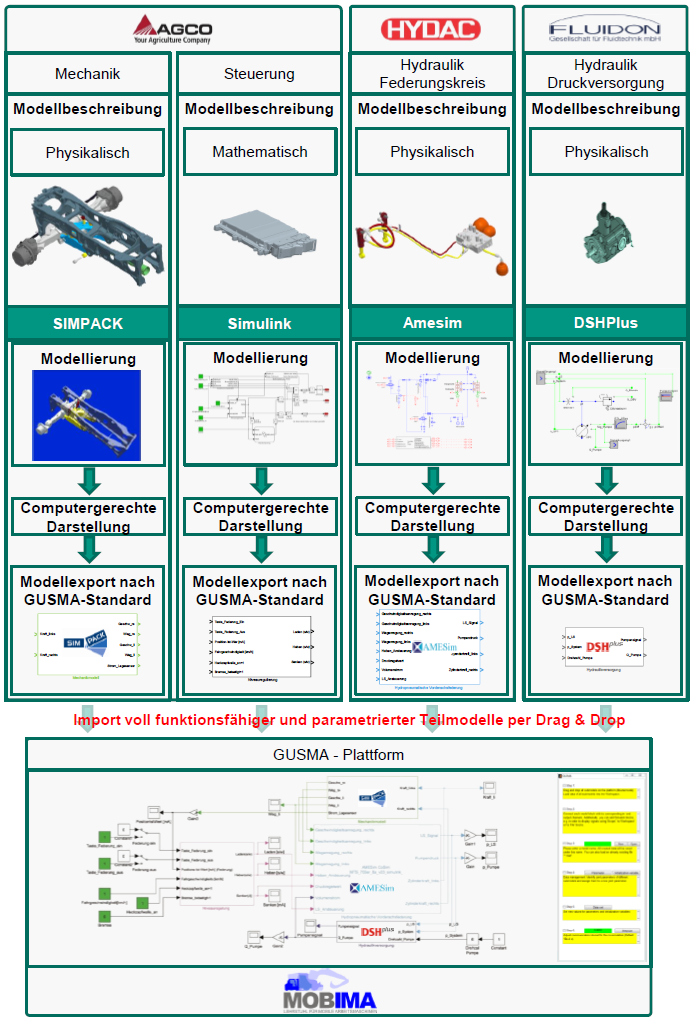

In order to make co-simulation usable for the purpose of cross-company simulation, a method for the coupled simulation of an entire system consisting of sub-models from different disciplines (e.g. electrics or electronics, control technology, mechanics or hydraulics) was developed in the project.

The partial models can be edited and parameterised by the user via "drag & drop". This modelling process is similar to the physical modelling of multi-domain software systems. However, the aspect that this can be done across departments or companies by pooling the expertise of manufacturers and suppliers enables a valuable time and cost advantage during the development process.

Proof of the applicability of the developed approach was provided using the example of a tractor front axle suspension, with particular attention being paid to the challenges of the mobile machinery sector, which is strongly characterised by small and medium-sized enterprises.

The developed standard was published as a VDMA guideline.