Hydrogen Systems

The growing use of hydrogen in the transportation sector calls for efficient and safe systems. Heavy-duty vehicles such as trucks, buses, and trains especially benefit from hydrogen as an energy carrier. In addition to onboard hydrogen systems, a reliable refueling infrastructure and standardized protocols are essential for the successful real-world deployment of this energy source.

FLUIDON supports you with innovative and field-proven simulation solutions for the development of future-proof hydrogen systems. Our accurate, physics-based simulations help you master temperature and pressure control, safety, and efficiency – paving the way for next-generation infrastructure.

Our Simulation Services for Hydrogen Refueling Systems

With DSHplus and our SaaS development platform Fluidon Cube, we offer tailored solutions for the design and optimization of hydrogen tank systems and refueling processes. Our tools enable you to develop specialized refueling protocols in a model-based and automated manner - whether based on SAE J2601 or customized according to customer requirements.

Our services include the development of simulation models, the provision of a cloud-based simulation infrastructure, and the creation of simulation workflows for comparative evaluation and optimization of system topologies and refueling strategies for hydrogen tank systems.

Typical tasks we handle for our customers include:

- Investigation of the thermal dynamics of tank systems during the refueling process

- Comparison and analysis of different fueling station concepts, such as cascade and booster refueling

- Development of efficient strategies for refilling vehicle and fueling station storage systems

- Simulation and optimization of subsystems and storage capacities based on specific requirements

- Analysis of the loading and unloading processes of tube trailers and vehicle tank systems

DALL·E - A clean and modern hydrogen refueling station with a truck or bus actively refueling

Interactive simulation: Optimize hydrogen refueling directly online

With our online simulation, you can calculate and visualize the refueling of a hydrogen tank system directly on our website. Simply enter the relevant system parameters such as desired refueling time, system pressure and temperature, or hydrogen pre-cooling, and start the simulation. Watch in real time how pressure, temperature, and fill level evolve during the refueling process. Test different scenarios and gain valuable insights into the dynamic behavior of your hydrogen tank systems.

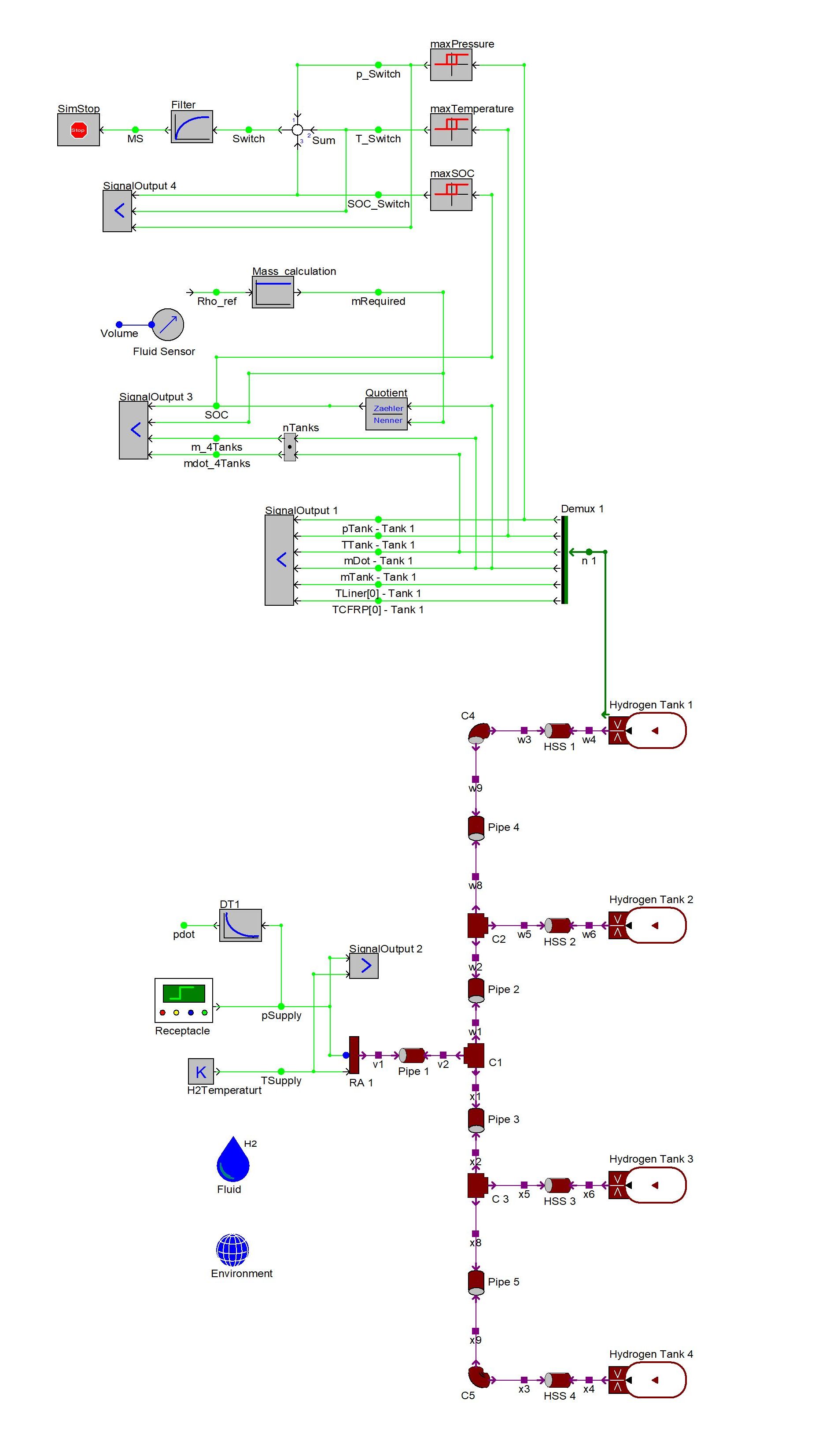

Model Description

The image on the right shows the structure of the simulated hydrogen tank system. The system consists of four identical tanks, each with a nominal volume of 350 liters. The simulation model is based on the benchmark model from the PRHYDE research project. The aim of the PRHYDE project was to develop a protocol and recommendations for the efficient refueling of 350-, 500-, and 700-bar high-pressure tanks of types III and IV.

The parameterization of the simulation model corresponds to the parameters published in the PRHYDE project (see graphic below).

Single Vessel Characteristics - Type IV Single Vessel (Large) (Quelle: PRHYDE-Projekt)

The following table lists the parameters that the user can specify within the given limits.

| Bezeichnung | Wert | Grenzen | Einheit |

|---|---|---|---|

| Refuelling Time | 600 | 0 - 1200 | s |

| Initial system pressure | 100 | +20 - +500 | bar |

| System temperature | 15 | -25 - +50 | °C |

| Initial system temperature | 15 | -40 - +85 | °C |

| Hydrogen temperature | -10 | -40 - +85 | °C |

| Target pressure | 350 | 20 - 875 | bar |

The calculation results of the simulation model for the benchmark simulations with 350, 500 and 700 bar are comparable with the results published in the PRHYDE project.

What happens next? What are the next steps?

Has the online simulation of the Fluidon Cube SaaS development platform sparked your interest?

Click here or on the red Simulation button to access the online simulation.

Learn more about how you can integrate the online simulation into your own website.