OptiELF - Optimising the energy efficiency of hydraulic systems in vehicles

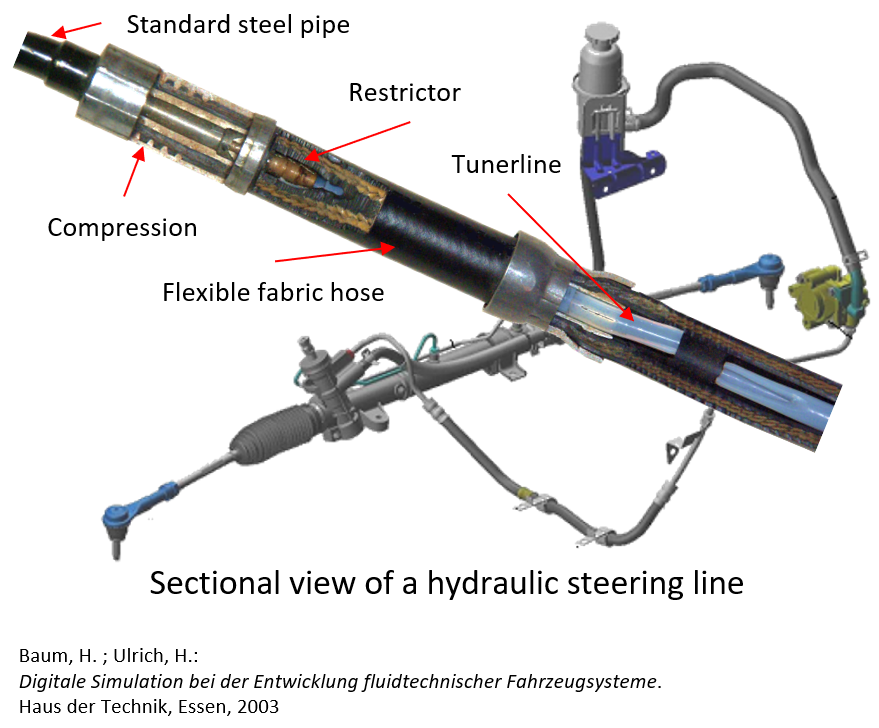

Expansion hoses, a combination of pipes, chokes, resonators and flexible high-pressure hoses, are an essential component of automotive hydraulic systems for reducing or completely eliminating the effects of pressure ripple caused by the pump, the resulting sound radiation at the steering gear and the vibration excitations at the chassis mounts. However, the "tuning measures" result in increased losses due to throttling during energy transmission and thus in higher energy consumption, which worsens the energetic efficiency of vehicle hydraulic systems.

The aim of the OptiELF project is to increase the energy efficiency of hydraulic power transmission by considering all subcomponents holistically while maintaining their acoustic/dynamic performance. As a result, the design of the expansion hose lines can be simplified and possibly even additional secondary measures for noise insulation can be dropped, so that a reduction in the system price can also be expected as a secondary benefit.

The development methodology can be used wherever hydraulic systems are found today in automotive engineering or in commercial vehicles in which, for acoustic reasons, the pump and actuator are connected by expansion hose lines or by a combination of steel and hose lines.

Motivation

Hydraulic power transmission systems consist of pump(s), pipes, valve(s) and consumer(s). When undesirable pressure oscillations occur, it is necessary to investigate the vibrational behaviour for different operating points of the system. To identify the cause of the problem, all components that influence the oscillatory behaviour must be included in the system analysis.

While pipes and valves, including their respective non-linearities, can still be represented quite easily in a time-domain-based simulation, the modelling of a pump suitable for analysing the vibrational behaviour of a hydraulic system is still very complex at present. A pump model is required that represents dynamic effects such as characteristic pressure- and rpm-dependent flow rate ripple or the pumps impedance.

In principle, physical pump models would be able to represent the required effects in the simulation, but their setup requires detailed knowledge of the design. The validation measurements and simulations that are still necessary are also very time-consuming and associated with high costs. For the short-term simulative analysis of vibration phenomena, the physical pump models can only be used to a very limited extent due to their lengthy computation times.

An alternative approach is needed, in which the pump in the system is measured for a short time under defined boundary conditions on an appropriately equipped test bench and this measurement data is then used, together with suitably adapted classical physical modelling approaches, to create the pump model.

Solution

Within the OptiELF project, a hybrid pump model was developed which uses a combination of component measurements and classical physical modelling approaches to represent the input impedance and the characteristic flow rate ripple of a pump or an actuator for numerical vibration analysis. The core of the hybrid pump model are measurements of the pump in two different test rig configurations.

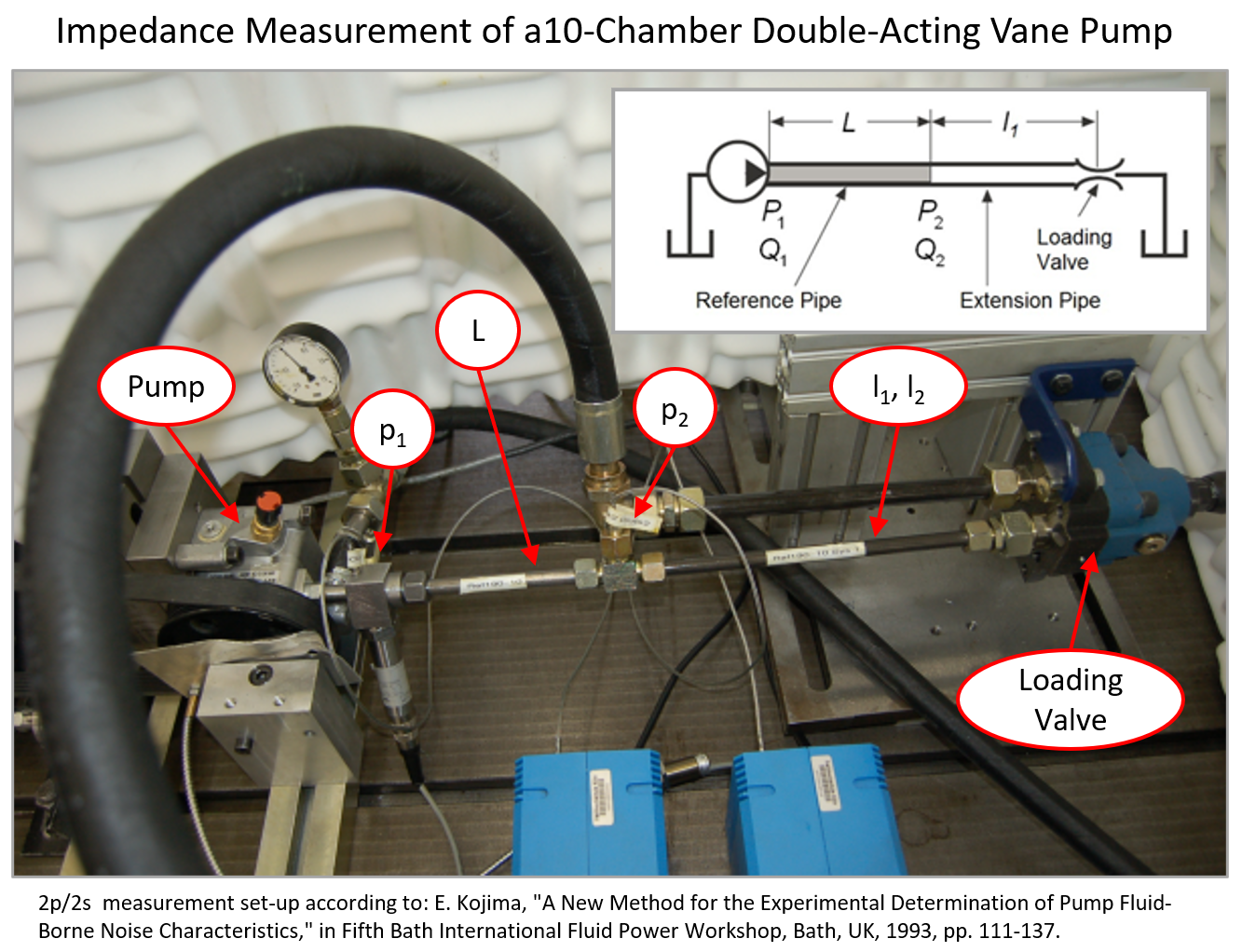

With the first test rig configuration, the pump impedance which depends on the operating point is determined for different rpm according to the "2-pressures/2-systems" (2p2s) method. In the simulation model, this impedance identified by measurement is represented by a physical sub-model based on an quarter-wave resonator pipe.

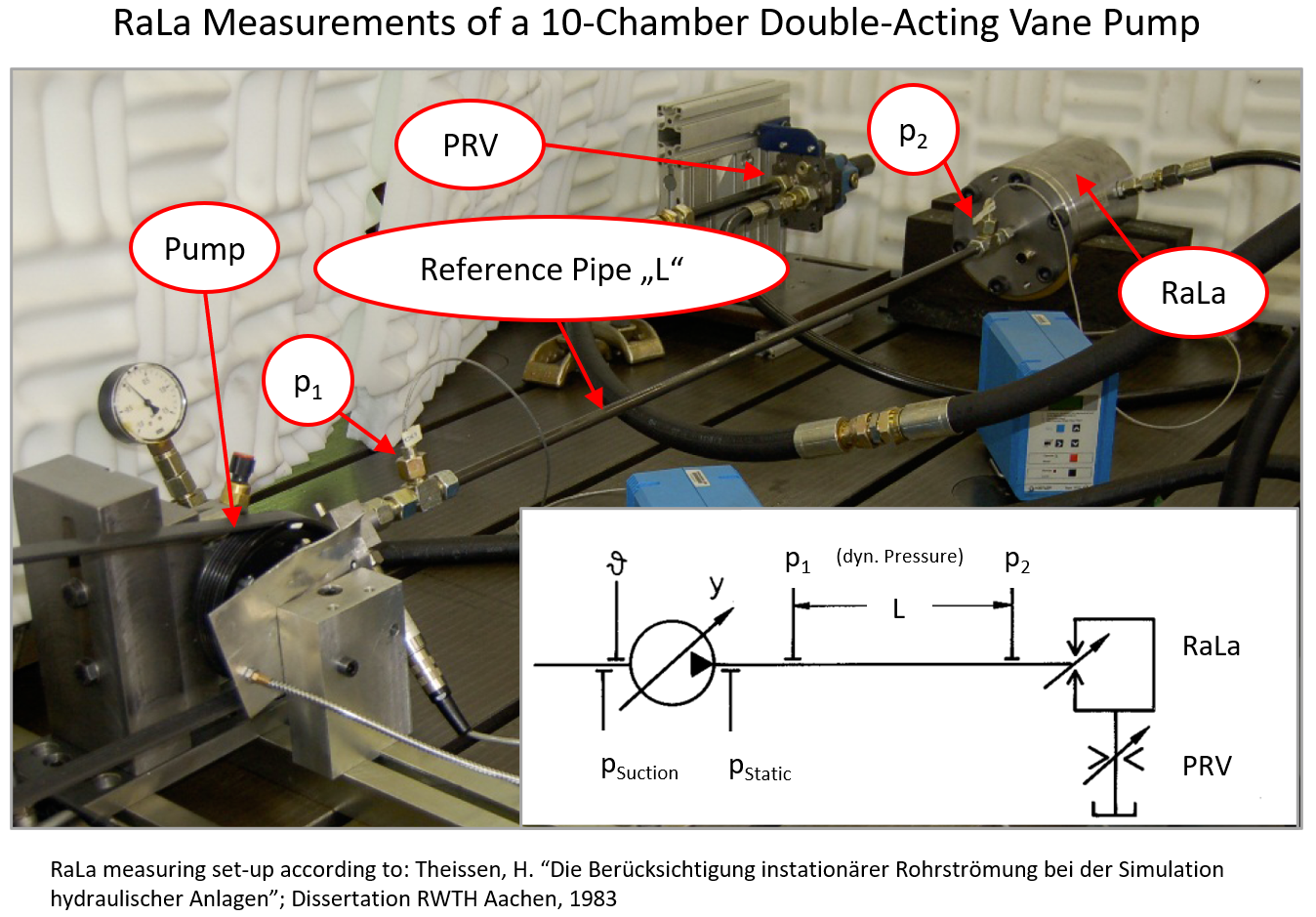

In the second test rig configuration, the pump is measured against a low-reflection line termination (RaLa) by varying the static pressure and the rpm level. After processing the RaLa measurement data, the characteristic flow rate ripple of the pump, which is dependent on the operating point, can be incorporated directly into the simulation model of the pump by means of a special multi-dimensional characteristic map.

The new hybrid pump model offers a suitable modelling approach for integrating the dynamics of an available actual pump into a system simulation. The hybrid pump model will always be a valuable tool when the focus of development work is on optimising the hydraulic piping system for a given pump. Various pipe configurations can be tested quickly by means of simulation, so that the optimum setup for the corresponding application can be determined much more rapidly and with less effort.

Related Publications

- Baum, H.; Becker, K.; Faßbender, A.: „Hybrid Pump Model for 1D Hydraulic System Simulation“; Modern Fluid Power - Challenges, Responsibilities, Markets; 9. International Fluid Power Conference (IFK); Seite 38-49; 2014; ISBN: 978-3-9816480-0-3

- Baum, H.; Becker, K.; Fassbender, A.: „Hybrides Pumpenmodell für die Systemsimulation - Synthese und messtechnische Ermittlung der Parameter“; Verein Deutscher Ingenieure / VDI-Gesellschaft Fahrzeug- und Verkehrstechnik; 2224 - Simulation und Erprobung in der Fahrzeugentwicklung, Seite 425-438; 2014; ISBN: 9783180922249